PF-EL

Copper Foil for Fine Patterning

Product form

| Copper Foil | PF-EL |

Applications

- Semiconductor package substrates

- High density multi-layer PWB

Features

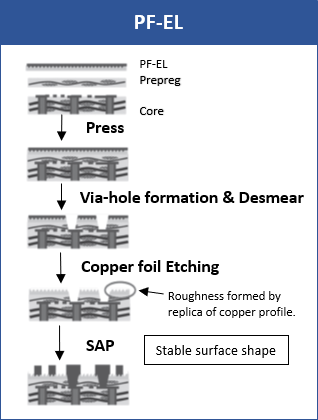

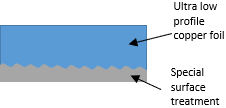

- PF-EL is a copper foil that is appropriate for fine line patterning with semi-additive process (SAP) using rough shapes of primer made with the copper profile.

- PF-EL has high peel strength for plating copper.

- High flexural modulus substrates with using prepregs.

Characteristics

Surface

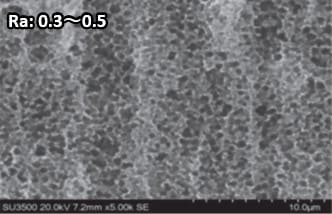

PF-EL

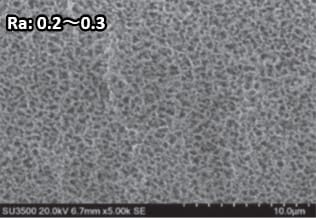

PF-EL SP

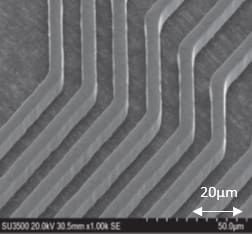

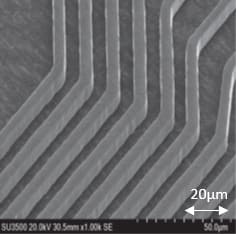

Fine patterning with SAP

Design

L/S=10/10 µm with PF-EL

(Exposure LDⅠ)

Design

L/S=7/7 µm with PF-EL SP

(Exposure LDⅠ)

Design

L/S=5/5 µm with PF-EL SP

(Exposure Stepper)

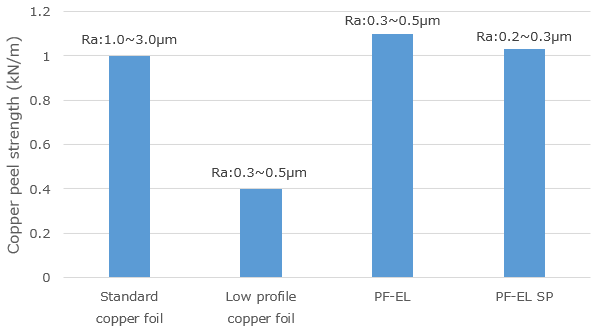

Copper peel strength

※ Sample: MCL-E-770G (Type R), Copper foil 1.5 µm with plating copper 20 µm

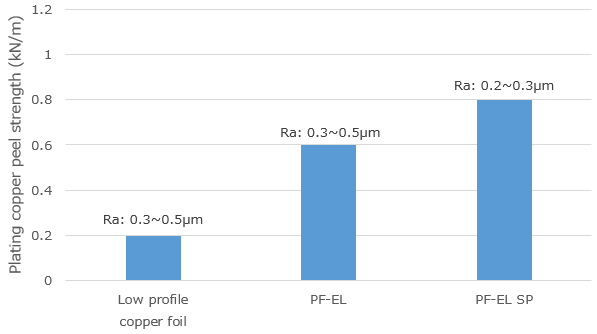

Plating copper peel strength

※ Sample: MCL-E-770G (Type R), plating copper 20 µm

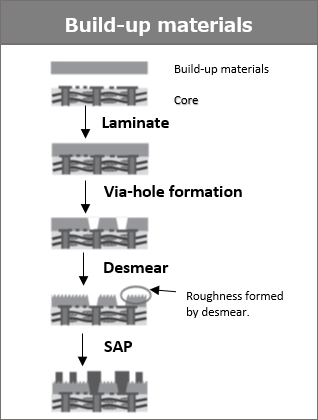

Fine patterning process

Standard Specifications

Copper Foil

| Part Number | Copper Foil Thickness (µm) |

Special Surface Treatment (µm) |

Roughness (µm) | Composition | Process |

|---|---|---|---|---|---|

| PF-EL-12 | 12 | 4 | Ra: 0.3–0.4 |  |

SAP ※1 |

| Rz: 1.5–2.5 | |||||

| PF-EL-3 | 3 | 2,4 | Ra: 0.3–0.5 | SAP ※1 MSAP ※2 |

|

| Rz: 1.5–2.5 | |||||

| PF-EL-2 | 2 | 2,4 | Ra: 0.3–0.5 | ||

| Rz: 1.5–2.5 | |||||

| PF-EL-1.5 | 1.5 | 2 | Ra: 0.3–0.5 | ||

| Rz: 1.5–2.5 | |||||

| PF-EL-1.5SP | 1.5 | 2 | Ra: 0.2–0.3 | ||

| Rz: 1.0–2.0 |

※1 After lamination of the material to the prepreg, the copper foil is etched out,and the special surface treatment with appropriate roughness made by a replica of the copper profile etched out remains on prepreg surface.This process is SAP using this replica.

※2 Semi additive process using thin copper foil as seed layer for having E’less copper +copper on both patterming and via plating purpose.

Inquirer about product

Please subscribe our technology eNewsletter!

Inquiry about product

Please inquire about product, technology or samples from here.