MCL-E-78G

Halogen Free, Low Dielectric Constant, High Tg, High Heat Resistance Multilayer Material

Product form

| CCL | MCL-E-78G |

| Prepreg | GEA-78G |

Applications

- Smartphone.

- Tablet PC.

Features

- Halogen-free with low dielectric property.

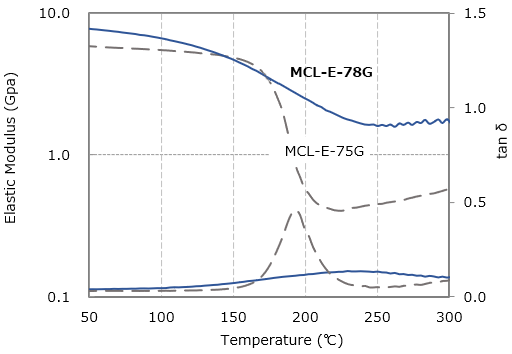

(Dk 3.5(@1GHz, Resin content. = 70%)) - High Tg and elastic modulus is higher than that of standard FR-4 at high temperature.

- Superior heat resistance. (Suitable for lead free process)

Characteristics

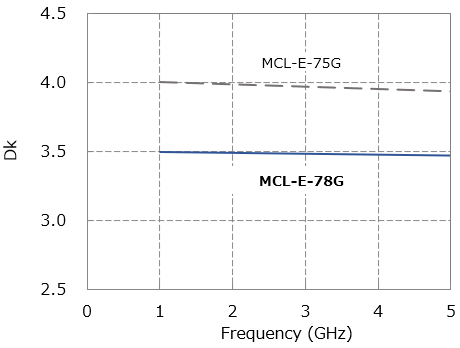

Correlation between Dielectric Constant and Frequency

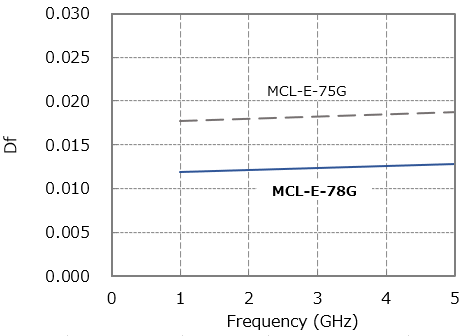

Correlation between Dissipation Factor and Frequency

Elastic Modulus

Copper Clad Laminate

(t0.8mm)

| Item | Condition ※3 | Unit | Actual Value | Reference (IPC-TM-650) |

||

|---|---|---|---|---|---|---|

| MCL-E- 78G |

||||||

| Tg | TMA method | A | ℃ | 160–170 | 2.4.24 | |

| DMA method | A | 200–220 | – | |||

| CTE ※1 | X (30–120℃) | A | ppm/℃ | 13–15 | – | |

| Y (30–120℃) | 15–17 | |||||

| Z | <Tg | A | 35–45 | 2.2.24 | ||

| >Tg | A | 180–230 | ||||

| Solder Heat Resistance (260℃) | A | sec. | >300 | – | ||

| T-260 (Without Copper) | A | min. | >60 | 2.4.24.1 | ||

| T-288 (Without Copper) | A | >60 | ||||

| Decomposition Temperature (TGA method 5% Weight Loss) | A | ℃ | 380–400 | 2.3.40 | ||

| Copper Peel Strength | 18 µm | A | kN/m | 1.0–1.2 | 2.4.8 | |

| 35 µm | A | 1.1–1.3 | ||||

| Flexural Modulus (Lengthwise) | A | GPa | 23–29 | 2.4.4 | ||

| Dielectric Constant ※2 (R.C.: 70%) |

1GHz | A | – | 3.4–3.6 | JPCA TM-001 | |

| 10GHz | 3.3–3.5 | |||||

| Dissipation Factor ※2 (R.C.: 70%) |

1GHz | A | – | 0.009–0.011 | ||

| 10GHz | 0.012–0.014 | |||||

| Volume Resistivity | C-96/40/90 | Ω・cm | 1×1014–1×1016 | 2.5.17 | ||

| Surface Resistance | C-96/40/90 | Ω | 1×1013–1×1015 | |||

| Insulation Resistance | A | Ω | 1×1014–1×1016 | – | ||

| D-2/100 | 1×1012–1×1014 | – | ||||

※1 Heating Rate: 10℃/min.

※2 Measured by Triplate-Line Resonator.

※3 Refer to“Condition Note”

※ Above data are experimental results and not guaranteed.

Standard Specifications

Copper Clad Laminate

| Part Number | Type | Copper Foil Thickness | Code Name | Laminate Thickness |

|---|---|---|---|---|

| MCL-E-78G | – | 12, 18, 35 µm | 0.04 | 0.04mm |

| 0.05 | 0.05mm | |||

| 0.06 | 0.06mm | |||

| 12 µm 18 µm 35 µm 70 µm |

0.07 | 0.07mm | ||

| 0.08 | 0.08mm | |||

| 0.09 | 0.09mm | |||

| 0.1 | 0.10mm | |||

| 0.15 | 0.15mm |

※ The thickness means that of dielectric layer.

Prepreg

| Part Number | Type | Glass Cloth | Properties | ||

|---|---|---|---|---|---|

| Style | Resin Content (%) |

Dielectric Thickness after Lamination ※1 (mm) |

|||

| GEA-78G | 0.03 | (1027N72) | 1027 | 72±2 | 0.044 |

| 0.04 | (106N70) | 106 | 70±2 | 0.051 | |

| 0.04 | (106N72) | 106 | 72±2 | 0.056 | |

| 0.04 | (1037N70) | 1037 | 70±2 | 0.049 | |

| 0.04 | (1037N74) | 1037 | 74±2 | 0.058 | |

| 0.05 | (1067N69) | 1067 | 69±2 | 0.061 | |

| 0.05 | (1067N72) | 1067 | 72±2 | 0.069 | |

| 0.06 | (1080N62) | 1080 | 62±2 | 0.075 | |

| 0.06 | (1078N62) | 1078 | 62±2 | 0.075 | |

| Reference (IPC-TM-650) | 2.3.16 | – | |||

※ Dielectric thickness after lamination is defined as the thickness of one sheet of prepreg when the resin flow is 0%. Value changes depending on the press condition or inner layer pattern.

Inquirer about product

Please subscribe our technology eNewsletter!

Inquiry about product

Please inquire about product, technology or samples from here.