Book individual appointments with our staff and material experts to discuss the latest material solution trends at PCIM 2023.

Products line-up we offer in PCIM

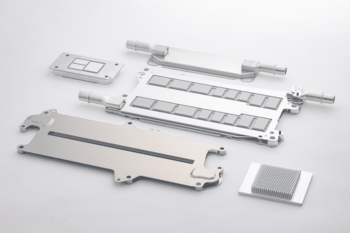

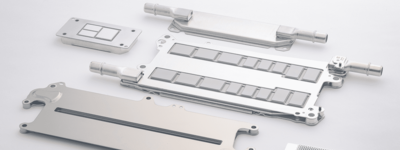

Aluminium Cooling Device

The amount of heat generated increases as power semiconductors will need higher output.

We propose a cooler equipped with aluminum fins, which has a fin shape changed from straight to corrugated or pin-shaped and has an expanded heat transfer area for High performance coolers for higher functionality and weight saving.

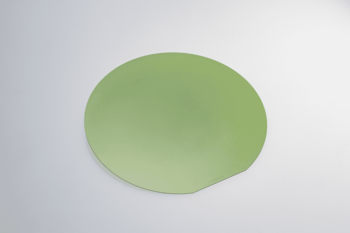

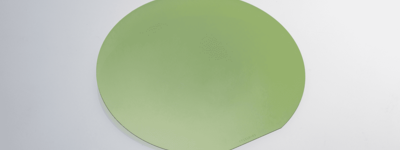

SiC Epitaxial Wafer

The size of chips which are introduced to vehicle drive system power modules require a larger output for high power.

HGE-2G is a SiCepitaxial wafer which defect density is less than 1/2 or less compared to the conventional ones due to the sophistication of the epitaxial growth process.The defect rate of device chips caused by epitaxial wafers can be reduced to 10% or less for 1 cm square chips.

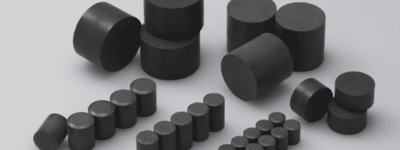

High Tg Epoxy Molding Compound

Application of high power and high density devices such as SiC are increasing rapidly in the market. Therefore more heat is generated during operation.

We have developed several high performance epoxy molding compounds which have excellent heat resistance (Tg~270ºC, low weight loss at high temperature), lower warpage, and excellent adhesion strength with various metal which lead to higher reliability of power semiconductor package/power module.

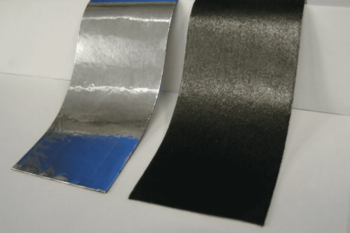

High Heat Resistant Coating Material “HIMAL”

The delamination between molding compounds and substrates is caused by a difference in thermal stress between power semiconductor component materials.

Our high heat resistant coating material “HIMAL” has a good heat resistance (Tg of 220ºC/ 336ºC and thermal decomposition temperature of 410ºC/ 376ºC). Even under severe temperature environments the delamination problem is prevented by the high adhesiveness and flexibility of HIMAL with its good reliability.

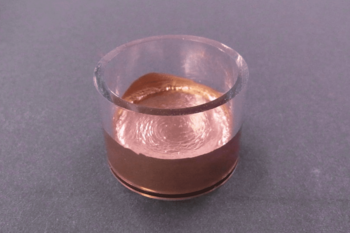

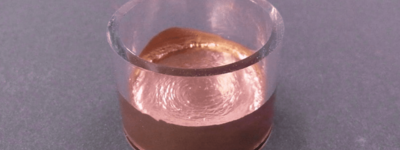

Copper Sintering Paste

Although high-lead solder is widely used in die-bonding applications for semiconductor chips, its thermal conductivity is limited to around 30W/(m・K)and the amount of thermal conduction is insufficient.

We have developed “copper sintering paste,” which has higher thermal conductivity 300W/(m・K) with low thermal compression pressure, which allows for die-bonding without breaking of chips and achieve high bonding reliability even at Tj over 200ºC.

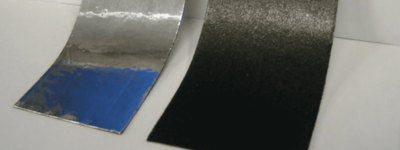

Thermal conductive adhesive materials

High thermal conductivity 90 W/(m・K) sheet with vertically oriented graphite fillers ensuring good flexibility for TIM applications.

Excellent both contact thermal resistance and bulk thermal resistance provide lower thermal resistance than the other materials even with thick sheet.

Aluminum Cooling Device

High performance cooler ensuring an expanded heat transfer area leading to higher functionality and weight saving.

SiC Epitaxial Wafer

Reduces SiC chip defect rate to less than 10%.

High Tg Epoxy Molding Compound

High Tg (>230 ℃) Epoxy molding compound for transfer molding process. Low warpage, high adhesive and low stress material.

High Heat Resistant Coating Material “HIMAL”

Himal prevents delamination between molding compounds and power semiconductor chips, boards, bonding materials, and others.

Copper Sintering Paste

Higher connection reliability compared to high lead solder or sintered silver. Provides 300 W /(m ・ K) of thermal conductivity.

Thermal conductive adhesive materials

High thermal conductivity 90 W/(m・K) sheet with vertically oriented graphite fillers ensuring good flexibility.

Prease send your request to us

If you can’t access registration form, please send your request directoly from here.