May 14, 2025

Resonac Corporation (President and CEO: Hidehito Takahashi, hereinafter “Resonac”), Nippon Steel Corporation (President and COO: Tadashi Imai, hereinafter “Nippon Steel”), Nippon Steel Engineering Co., Ltd. (President: Yukito Ishiwa, hereinafter “Nippon Steel Engineering”), and the University of Toyama (President: Shigeru Saito, hereinafter “the University of Toyama”) have proposed the project “Research and Development on Glycine Production via Methanol Derived from CO2” (hereinafter “the Project”) in response to the call for proposals by the New Energy and Industrial Technology Development Organization (hereinafter “NEDO”) for “Carbon Recycling and Next-Generation Thermal Power Generation Technology Development / CO2 Emission Reduction and Utilization Technology Development.” The Project was selected on May 1.

The research and development period for the Project is planned to be from FY2025 to FY2027.

Background and Objectives of the Research

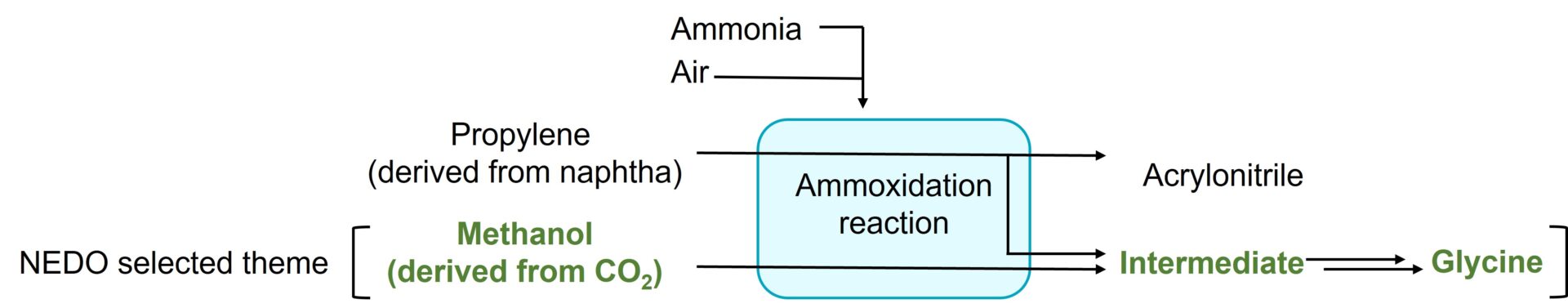

As a response to climate change, reducing CO2 emissions has become a critical issue, and technologies that utilize CO2 as a resource are gaining attention. Glycine is an important chemical used in agrochemicals, health foods, food products, and electronic materials. Currently, it is mainly produced from intermediates derived from propylene sourced from naphtha, and methanol sourced from natural gas. However, if glycine can be produced from methanol derived from CO2 emitted by steel plants, thermal power plants, etc., rather than from fossil fuels, it will promote carbon recycling and significantly reduce CO2 emissions.

The four parties aim to promote carbon recycling by converting the production of glycine, which is expected to see increasing demand, from fossil fuel-derived sources to CO2-derived sources emitted by steel plants, thermal power plants, etc.

A method for producing glycine from CO2 via methanol (ammoxidation reaction)

Overview of the Joint Research

The Project aims to establish technology for the integrated production of glycine from CO2 emitted by steel plants, thermal power plants, etc.

Specifically, it will develop a practical catalytic process for synthesizing methanol at low temperatures, utilizing the results obtained from the “Carbon Recycling and Next-Generation Thermal Power Generation Technology Development / CO2 Emission Reduction and Utilization Technology Development / CO2 Utilization Technology Development for Chemical Products / Technology Development for Para-xylene Production from CO2“*1 conducted by Nippon Steel, Nippon Steel Engineering, and the University of Toyama from FY2020 to FY2024.

Meanwhile, Resonac, which has a plant at its Kawasaki Plant for producing acrylonitrile from propylene via ammoxidation reaction, possesses the technology and know-how for the stable and high-quality integrated production of high-value-added glycine from intermediates obtained by simultaneously inputting high-purity methanol derived from natural gas.

Although CO2-derived methanol is expected to contain different types and amounts of impurities compared to fossil fuel-derived methanol, the four parties will develop and optimize a new catalytic process for ammoxidation reaction based on Resonac’s proprietary manufacturing technology to utilize these impurities on an industrial scale. The goal of the Project is to develop technology that maintains the current quality of glycine while significantly reducing CO2 emissions from an LCA*2 perspective and to achieve early social implementation.

The anticipated research and development tasks and the roles of the four parties are as follows:

1) Improvement of catalysts for synthesis of CO2-derived methanol (Nippon Steel, Resonac, University of Toyama (Joint research partner))

2) Mass production of catalysts for synthesis of CO2-derived methanol (Nippon Steel, Nippon Steel Engineering, Resonac)

3) Development of intermediate and glycine production processes from methanol (Resonac)

4) Development of an integrated optimal process for glycine production from CO2-derived methanol

4-1) Examination of CO2-derived methanol synthesis processes suitable for intermediate and glycine production (Nippon Steel, Nippon Steel Engineering)

4-2) Optimization of intermediate and glycine production processes using CO2-derived methanol (Resonac)

- *1July 14, 2020, NEDO “Commencement of Technology Development for Chemical Products (Para-xylene) Production from CO2”(Japanese)

- *2Abbreviation for Life Cycle Assessment. It evaluates and assesses the environmental impact of a product throughout its lifecycle, from raw material extraction to manufacturing, consumption, disposal, and recycling.

About Resonac

Resonac is a functional chemical company that produces and sells products related to semiconductor and electronic materials, mobility, innovation enabling materials, chemicals, etc. The Company has a wide variety of materials and advanced material technologies applicable to midstream to downstream of supply chains of various products. In January 2023, Showa Denko and former Hitachi Chemical merged into Resonac. The trade name “RESONAC” was created as a combination of two English words, namely, the word of “RESONATE” and “C” as the first letter of CHEMISTRY. As a “co-creative chemical company,” Resonac aims to continue growing and enhance its corporate value through co-creation.

The Company recorded net sales of about 1.4 trillion yen in 2024, and its overseas sales accounted for 56% of net sales. The Company has deployed production/sales bases in 24 countries and regions and continues operating its business globally (as of February 2025).

Resonac Holdings Corporation: https://www.resonac.com/

About Nippon Steel Corporation

Nippon Steel is Japan’s largest and one of the world’s leading steel manufacturers, with manufacturing bases in Japan and over 15 countries worldwide. The Nippon Steel Group promotes four business areas: steelmaking, engineering, chemicals & materials, and system solutions. The four pillars of its management plan are “Reconstruction of Domestic Steelmaking Business and Strengthening Group Management,” “Promotion of Global Strategy for Evolution and Expansion of Overseas Business,” “Challenge towards Carbon Neutrality,” and “Promotion of Digital Transformation Strategy.” Aiming to be the “world’s No.1 comprehensive steel manufacturer,” Nippon Steel pursues the highest level of technology and manufacturing capabilities, contributing to societal development through the provision of excellent products and services.

Nippon Steel Corporation: https://www.nipponsteel.com/en/

About Nippon Steel Engineering

Nippon Steel Engineering Co., Ltd. is an engineering company rooted in steelmaking, expanding its business in various fields such as “Environment & Energy,” “Urban Infrastructure,” “Service Business,” and “Steel Plant.” It engages in the construction and O&M of various plants and facilities, including waste power generation, renewable energy (offshore wind, biomass, geothermal, etc.), combined heat and power (CHP), oil & gas development, pipelines, and logistics facilities such as steel structure buildings, sales of components such as seismic isolation devices, and advanced digital technology utilization and implementation in power solutions and energy management services. Nippon Steel Engineering contributes to the construction of an environmentally harmonious society and the development of a resilient and sustainable society.

Nippon Steel Engineering Co., Ltd.: https://www.eng.nipponsteel.com/en/

About University of Toyama

The University of Toyama, celebrating its 20th anniversary, was reorganized and integrated in 2005 from the former Toyama University, Toyama Medical and Pharmaceutical University, and Takaoka National College. It is one of Japan’s leading comprehensive national universities, with over 9,300 students and 2,500 faculty and staff members across nine faculties (Humanities, Education, Economics, Science, Medicine, Pharmacy and Pharmaceutical Sciences, Engineering, Art and Design, Sustainable Design) and multiple educational and research organizations, including the affiliated hospital and the Institute of Natural Medicine. In the Impact Rankings 2024, which evaluates social contribution efforts using the SDGs framework, the University of Toyama ranked 30th domestically and 601-800th globally, receiving high praise. The University of Toyama constantly challenges new endeavors, aiming to be an “interesting university.”

University of Toyama: https://www.u-toyama.ac.jp/en/