October 16, 2025

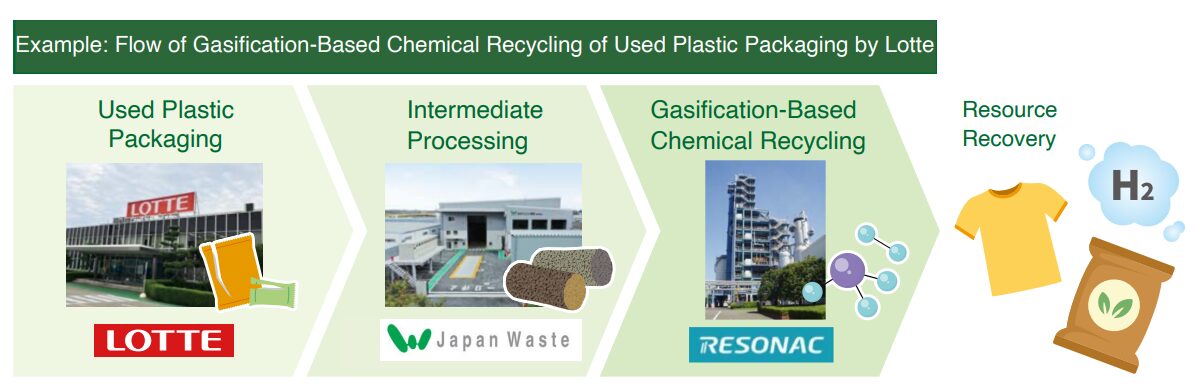

Lotte Co., Ltd. (Head Office: Shinjuku-ku, Tokyo; President and Representative Director: Hideki Nakashima; hereinafter “Lotte”) and Resonac Corporation (Head Office: Minato-ku, Tokyo; President and CEO: Hidehito Takahashi; hereinafter “Resonac”) will begin chemical recycling of used plastic packaging from production losses through gasification at Lotte’s Sayama Plant (Sayama City, Saitama Prefecture) in October 2025. This initiative is being carried out in collaboration with Japan Waste Group (hereinafter “Japan Waste”). The traceability of this initiative is ensured through a third-party certification system: used plastic packaging waste generated at the Lotte Sayama Plant is collected and pre-processed by Japan Waste, then chemically recycled by Resonac. The resulting chemical products—such as hydrogen, ammonia, and carbon dioxide—are returned to the market through Resonac’s supply chain.

Plastic films used in packaging are typically made from laminate structures combining various types of plastics and aluminum vapor-deposited layers to preserve product quality. Due to the difficulty of separating these materials, there are limited options for effective utilization. Lotte has previously converted most of its used plastic packaging into RPF (Refuse Paper and Plastic Fuel)* for thermal recycling. However, as society increasingly demands more advanced utilization of used plastics, there is a growing need to shift toward material and chemical recycling.

The chemical recycling method employed in this initiative involves gasifying used plastics at high temperatures to break them down to the molecular level and regenerate them into chemical products. By transitioning from thermal recycling to gasification-based chemical recycling, Lotte aims to promote the resource recovery of used plastic packaging. In fiscal 2025, approximately 10 tons of plastic waste generated at the Sayama Plant is expected to be chemically recycled through gasification.

In recent years, global attention has focused on the environmental challenges posed by used plastics, including marine plastic pollution, microplastics, and greenhouse gas emissions from incineration. These issues have prompted calls for more sustainable waste management practices.

Lotte has identified “Circular Economy” as one of the six material issues in its long-term sustainability vision, “Lotte Mirai Challenge 2048.” The company is committed to minimizing negative environmental impacts across the entire value chain—from raw material procurement to consumption and disposal—while striving to realize a circular economy. This initiative is part of that commitment. Lotte will continue to explore advanced methods for reducing plastic waste and promoting resource circulation in collaboration with stakeholders.

Resonac places sustainability at the core of its management philosophy and promotes cross-sector co-creation to realize a decarbonized and circular society. Through the expansion of its chemical recycling business and advancement of related technologies, Resonac aims to achieve both enhanced resource circulation and decarbonization. This initiative leverages the company’s expertise in gasification-based chemical recycling of plastics, which has been in continuous commercial operation at its Kawasaki Plant (Kawasaki City, Kanagawa Prefecture) since 2003—the only such facility in the world. By recycling used plastics and textiles into low-carbon chemical products, Resonac contributes to reducing environmental impact and promoting effective resource utilization.

*RPF (Refuse Paper and Plastic Fuel): A solid fuel made from waste plastics and recovered paper. It is considered an important recycling method that contributes to decarbonization by serving as an alternative to fossil fuels.

[About Lotte]

Founded in June 1948, Lotte is a confectionery manufacturer committed to its purpose of “Connecting people and creating a happier future through original ideas and moving experiences.” As part of its sustainability vision “Lotte Mirai Challenge 2048,” which targets the company’s 100th anniversary, Lotte has identified “Circular Economy” as one of its six material issues. The company aims to minimize environmental impact across the entire value chain—from raw material procurement to consumption and disposal—while striving to realize a circular economy.

LOTTE CO., LTD.: https://www.lotte.co.jp/english/

[About Resonac]

Resonac is a functional chemical company that produces and sells products related to semiconductor and electronic materials, mobility, innovation enabling materials, chemicals, etc. The Company has a wide variety of materials and advanced material technologies applicable to midstream to downstream of supply chains of various products. In January 2023, Showa Denko and former Hitachi Chemical merged into the Resonac. The trade name “RESONAC” was created as a combination of two English words, namely, the word of “RESONATE” and “C” as the first letter of CHEMISTRY. As a “co-creative chemical company,” Resonac aims to continue growing and enhance its corporate value through co-creation. The Company recorded net sales of about 1.4 trillion yen in 2024, and its overseas sales accounted for 56% of net sales. The Company has deployed production/sales bases in 24 countries and regions and continues operating its business globally (as of February 2025). For detail, please refer to our Website.

Resonac Holdings Corporation: https://www.resonac.com/