March 04, 2025

Resonac Corporation (President: Hidehito Takahashi; hereinafter “Resonac”) has signed a non-exclusive license agreement*1 concerning patented technology related to Scanning Probe Microscopy*2 (hereinafter “SPM”) with Shimadzu Corporation (President & CEO: Yasunori Yamamoto) on February 14. This technology provides new measurement metrics and is expected to be incorporated into optional software for the SPMs sold by Shimadzu Corporation. Through the utilization of this technology, Resonac aims to contribute to analysis in the field of materials science.

The advancement of nanotechnology is accelerating across various fields, including semiconductors, polymers, biotechnology, and food. In all these areas, analyzing material surfaces is crucial for creating superior materials and investigating the mechanisms behind the appearance of functions of materials.

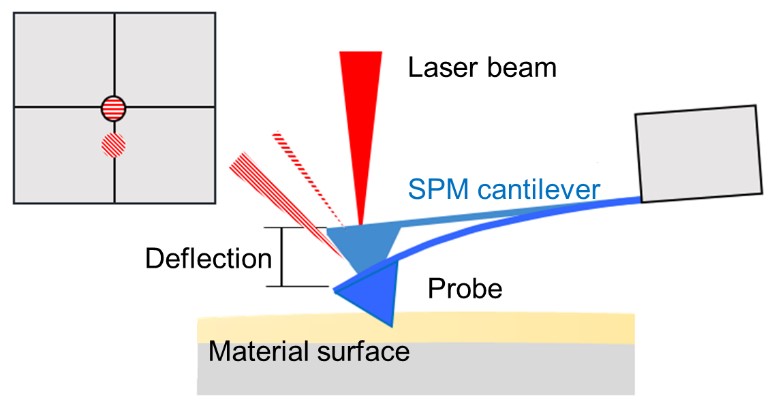

SPM is a type of microscope that can examine the fine topography of material surfaces at the nanometer scale and is widely used in industry. In SPM, a probe attached to the tip of a cantilever is brought close to the material surface, utilizing the forces exerted by the surface to output an image of the surface topography (Figure 1). When the measurement method is set to Force Curve Mode*3, it can output not only the topography but also adhesion forces*4 and modulus of elasticity*5 as microscope images. However, conventional techniques may have difficulty in obtaining clear images and require careful interpretation of the data.

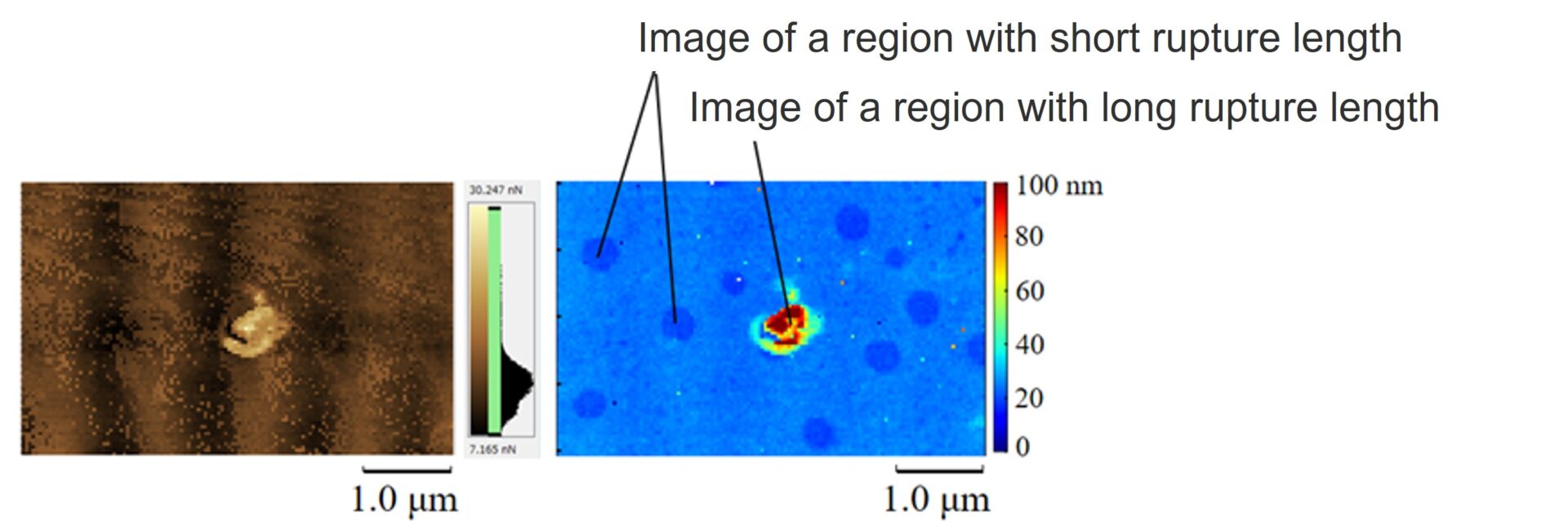

Resonac has focused on the distance at which an attractive force acts between the probe and the material surface during force curve measurements by SPM. Resonac has defined this distance as ” rupture length” and developed a technology that allows for efficient analysis of large amounts of data, enabling easy output of rupture length images. The rupture length images are capable of providing clear representations that cannot be obtained from adhesion force images or elastic modulus images (Figure 2). Moreover, this analysis allows us to assess not only whether the observed force is “strong or weak” but also whether it is “strong and long or strong and short”*6. Since rupture length images can be utilized as fundamental measurement metrics that represent the characteristics of material surfaces, we obtained a patent for the related technology in 2022. This technology can be applied to various material surfaces, particularly proving effective in the analysis of polymers and soft materials.

Figure 1: Schematic diagram of SPM equipment

Figure 2: Example of polymer surface observation (Left: Image from conventional technology – Adhesion force image; Right: Image from the Resonac’s new technology – Rupture length image)

Shimadzu Corporation is a leading domestic manufacturer of analytical and measurement instruments, providing SPM globally. The clarity and versatility of our technology’s images have been recognized by Shimadzu Corporation, leading to the conclusion of this contract between Resonac and Shimadzu Corporation. This technology is expected to be incorporated as optional software for the SPMs sold by Shimadzu Corporation.

Resonac will continue promoting “co-creation” based on its intellectual property, aiming for growth as a “Co-Creative Chemical Company” that can solve various social challenges.

- *1The right granted by the patent holder (Resonac) to a third party to implement the patented invention.

- *2A general term for microscopes that bring a fine needle close to the sample surface to detect the mechanical or electromagnetic interactions between the sample and the needle while scanning, allowing for three-dimensional observation of the sample surface.

- *3A method in which the probe of the SPM is swept vertically across the sample surface while measuring the force as the distance between the sample and the cantilever changes.

- *4The force that keeps two surfaces in contact with each other.

- *5A value that represents the resistance to deformation of a material (material hardness). Materials with a larger elastic modulus are harder to deform.

- *6“Strong and long” refers to a state that is tenacious and does not easily separate, while “strong and short” refers to a state where the force is strong as long as there is contact.