18 May 2023

Resonac Corporation (Tokyo: 4004) (President: Hidehito Takahashi; hereinafter, “the Company”) has acquired ISCC PLUS certification for the three products (hydrogen, ammonia and acrylonitrile) manufactured at its Kawasaki Plant in Kawasaki City, Kanagawa Prefecture. ISCC PLUS is an international certification system for sustainable products. The three products are all manufactured in the Company’s plastic chemical recycling business, in which used plastics are recycled into materials for chemical products, and the Company became the first in Japan to acquire ISCC PLUS certification for products made by using materials derived from used plastics.

At the Kawasaki Plant, the Company has been conducting a plastic chemical recycling business, which it calls “Kawasaki Plastic Chemical Recycling (KPR),” to recycle used plastics into materials for chemical products since 2003. Following the acquisition of ISCC PLUS certification, the Company will take the certification system-based mass balance approach to allocate recycled plastic content to the derivatives (three products shown below) made by using materials including those derived from used plastics chemically recycled at the KPR plant toward selling them as ISCC PLUS-certified products. The Company will coordinate with the related business partners to decide when to start implementing this initiative.

- Targeted products: Hydrogen, ammonia and acrylonitrile (AN)

- About ISCC PLUS certification

This international certification system is implemented by International Sustainability and Carbon Certification (ISCC) in its capacity as a third-party organization. The system is designed to verify whether or not the sustainability of biomass, recycled materials and products is ensured and appropriately managed across a supply chain. It is utilized as an effective certification system that adopts a mass balance approach to foster the generation of biomass and the use of recycled materials especially in the supply chain with a complicated production process.

- Mass balance approach

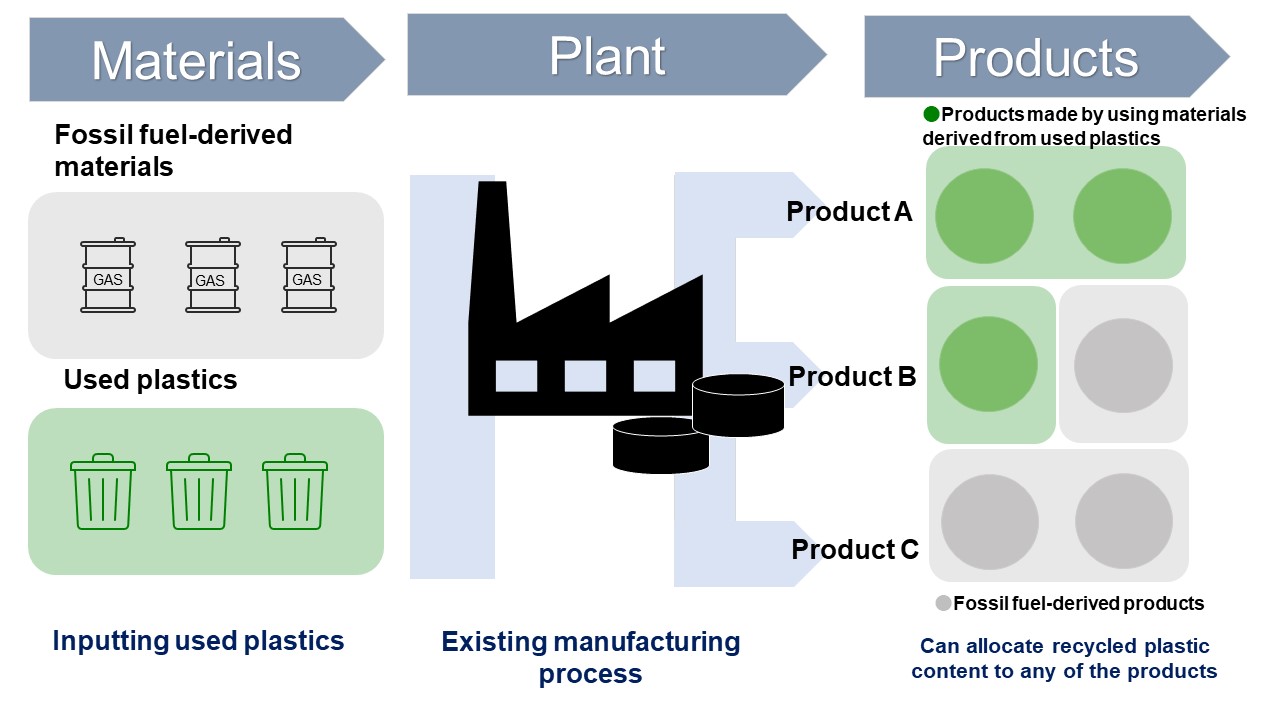

Manufacturers that make products by using both sustainable materials such as biomass and recycled materials and unsustainable materials can attribute sustainability to any one or more of the selected products in proportion to the amount of sustainable materials input into the production process. By taking this approach, the Company can contribute to the expanded use of sustainable materials while maintaining the current product quality and performance levels based on the effective use of the existing manufacturing process. Moreover, consumers can also contribute to the creation of a sustainable society by purchasing environment-friendly products thus manufactured. The mass balance approach is therefore expected to be more widely adopted across the chemical industry.

Illustrative image of the mass balance approach

- Resonac’s commitment to decarbonization and carbon neutrality

In the KPR process, collected used plastics are gasified through thermal decomposition to extract hydrogen and carbon monoxide from the plastics. Then the extracted carbon monoxide is processed into carbonic acid and dry ice products and the hydrogen is used as a material for ammonia. Also, the hydrogen derived from the plastics is supplied as an energy source for fuel cell vehicles and for fuel cells installed at hotel facilities. KPR is thus making contributions to the promotion of initiatives implemented for a decarbonized society. The Company will continue to introduce environment-friendly production equipment and technologies, proactively foster environmental measures, and supply products that support an advanced recycling-oriented society in its effort to promote the sustainable development of the global community, including the achievement of decarbonization and carbon neutrality across society.

(Reference)

– Plastic chemical recycling: https://www.resonac.com/rd/tech/environment.html

– Achieving carbon neutrality through clean ammonia production (in Japanese only): https://www.resonac.com/jp/corporate/unsung-leaders/20221207-1991.html

– Showa Denko’s Low-Carbon Ammonia Produced from Used Plastics Reduced CO2 Emission by more than 80%: https://www.resonac.com/news/2022/12/20/2265.html

– Growing lettuces at a hotel by making use of hydrogen derived from used plastics as an energy source under the Ministry of the Environment’s regional low-carbon hydrogen supply chain demonstration project (in Japanese only): https://www.resonac.com/jp/news/2020/12/24/280.html