December 15, 2025

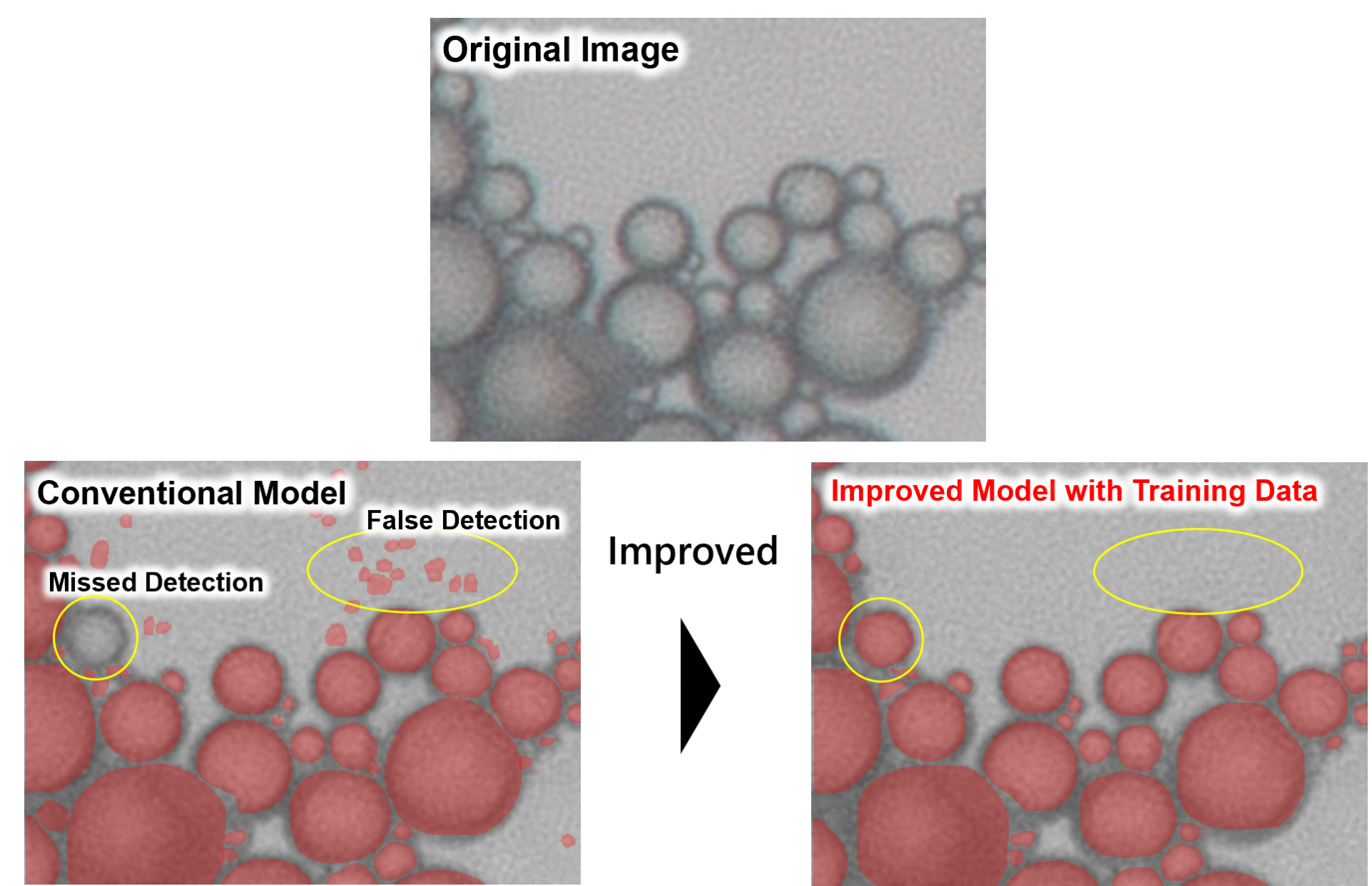

Resonac Corporation (President and CEO: Hidehito Takahashi, hereinafter referred to as “Resonac”) has introduced deep learning-based image analysis technology for materials inspection, achieving both higher accuracy and shorter inspection times through automation. In this time, the Research Center for Computational Science and Informatics (Hereinafter referred to as “RCCSI”) collaborated internally with the “Job Support Team,” a special group composed of neurodiverse talent*1, to produce high-quality training data. For spherical alumina*2 image inspection, the AI model trained on this data reduced the false detection rate from 40.8% to 3.2% compared to the previous model an approximate 40%*3 improvement in analysis accuracy.

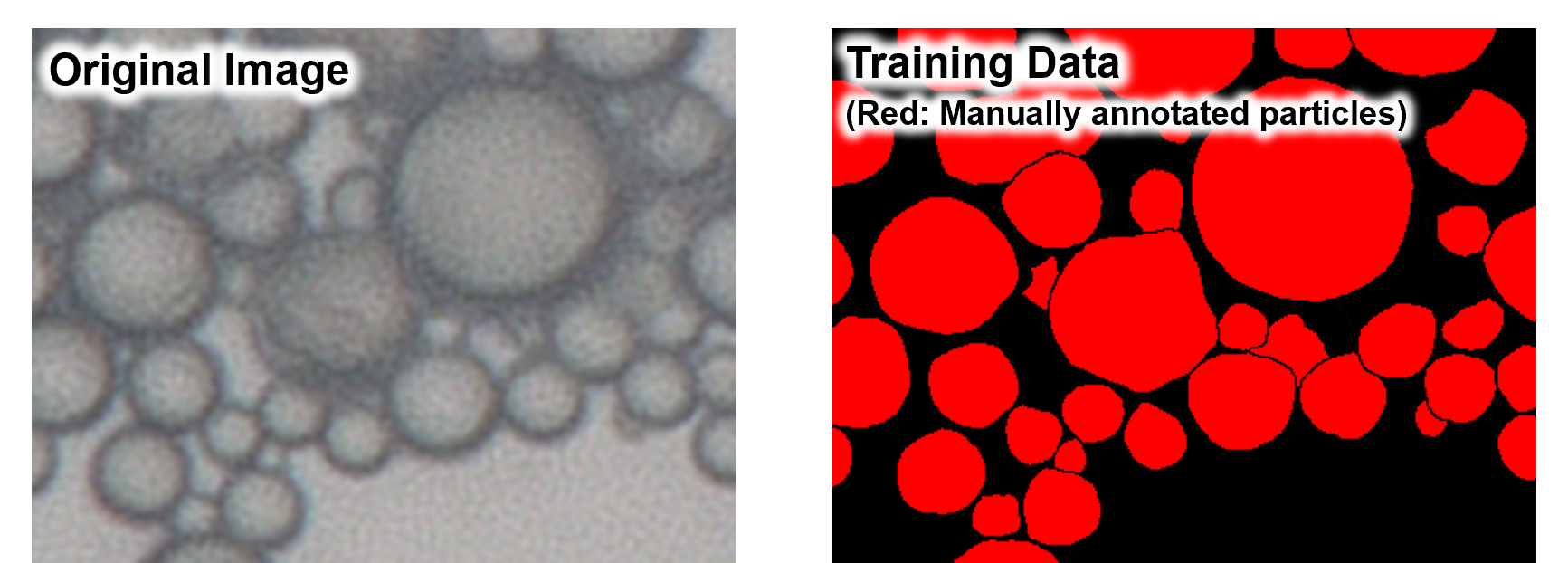

Automating inspections using deep learning requires training data that reflects the judgment of experienced inspectors. This data must be created with pixel-level precision, as even minor errors can significantly degrade analysis accuracy. The process involves manually color-coding each particle in the image, demanding high concentration and accuracy, and has been difficult to scale due to labor shortages.

Creating training data using a pen tablet

Working closely with RCCSI’s image analysis team, the Job Support Team took on the task of creating this training data. Their meticulous attention to detail and sustained focus—traits often associated with neurodiverse individuals—proved highly suited to the work, enabling rapid and accurate data production. By internalizing the training data creation process, Resonac has also built valuable expertise and established a system for continuously supplying high-quality data.

At the Toyama Plant of Resonac Ceramics Corporation (President: Naoya Takahashi), the spherical alumina image analysis model trained with Job Support Team data showed a dramatic reduction in false detection rate from 40.8% to 3.2% compared to the previous model. This improvement enables further enhancement of the accuracy of pass/fail determinations for alumina particles in next analysis steps, and by feeding these results back into manufacturing conditions, further productivity gains are expected.

Example: Spherical alumina image and corresponding training data

Comparison of results: conventional model vs. improved model using training data

A member of Job Support Team commented:

“We take pride in our responsibility for work that directly impacts Resonac’s product quality and corporate credibility. Above all, we are proud to be part of Resonac.”

Resonac places great importance on “creating an environment where diverse talent can thrive in the workplace with peace of mind,” with a strong commitment to disability inclusion. In 2013, as part of its Diversity Project, the predecessor of Resonac, Showa Denko, launched a promotion team to accumulate know-how in employing individuals with intellectual, mental, and developmental disabilities, aiming to expand these practices across offices and group companies. In 2015, this initiative evolved into the Job Support Team, which promotes employment, development, and retention of employees with disabilities. The team has expanded its responsibilities to include internal mail delivery, conference room maintenance, and more. In recent years, the team has supported the creation of over 70 internal e-learning contents annually, contributing significantly to knowledge sharing and talent development across the Resonac Group. Building on these achievements, the team continues to challenge new field of work, striving to create high value-added innovations that directly enhance product quality and corporate value under the slogan “We change unique personality into power.” through automation and efficiency.

*1 Neurodiverse talent refers to individuals with diverse cognitive characteristics and abilities stemming from neurological traits. This concept affirms such diversity as a positive aspect of human individuality, rather than viewing developmental, mental, or intellectual disabilities as “deficits” or “disabilities.”

*2 Spherical alumina is a material made by melting alumina in a high-temperature flame to form spherical particles ranging from several micrometers to 90 micrometers in diameter. With excellent thermal conductivity, fluidity, and packing properties, it is used as a filler in heat dissipation sheets for electronic components.

*3 Resonac survey. Comparison of false detection rates in spherical alumina image inspection between the conventional model (April 2025) and the improved model using training data (November 2025).