October 15 2025

Resonac Corporation (President and CEO: Hidehito Takahashi, hereinafter “Resonac”) has developed a magnetic molding compound for inductors with bending strength*1 improved by 1.4 times compared to our conventional products. This material is used in inductors*2 for devices such as smartphones, helping to prevent performance degradation caused by impact or humidity, thereby enhancing device reliability. Mass production is scheduled to begin in 2026.

For this development, Resonac applied its proprietary advanced reaction analysis based on quantum chemical calculations to study the bonding mechanism between resin and magnetic powder in the molding compound. This approach enabled us to complete development in one-third of the conventional time, significantly accelerating time-to-market.

With the rapid expansion of technologies such as AI (Artificial Intelligence), 5G (5th Generation Mobile Communication System), and ADAS (Advanced Driver-Assistance Systems), devices from smartphones to xEVs (electric vehicles) require more complex functions, including noise suppression and voltage control. As a result, demand for inductors and magnetic molding compound is increasing, along with higher performance requirements. The reliability of magnetic molding compound has become directly linked to the overall quality of the final product.

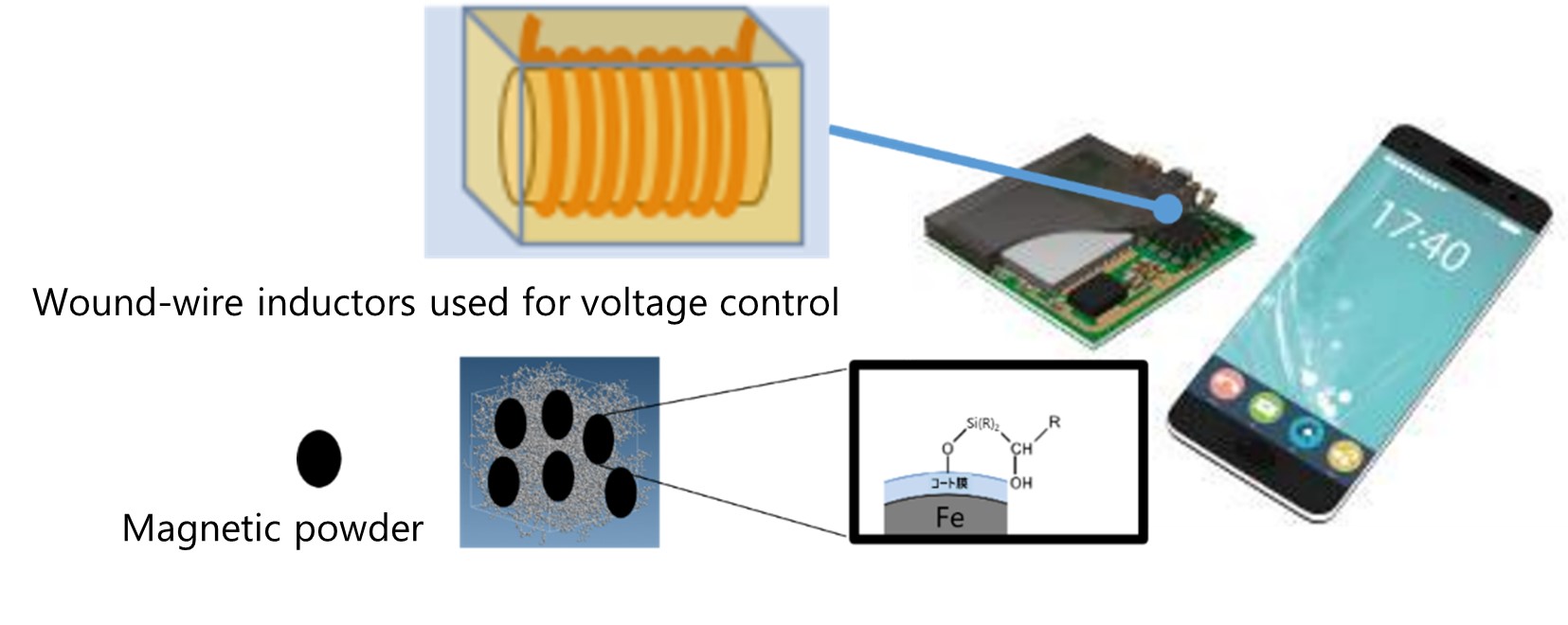

Wound inductors, commonly used in power circuits, are formed by molding wound wire with a magnetic molding compound composed of resin and magnetic powder. However, insufficient bonding strength at the resin–magnetic powder interface can cause the material to break under external force after mounting, leading to reliability issues. Therefore, improving the bonding strength between resin and magnetic powder has been a key challenge.

Example of inductor mounting and image of magnetic molding compound

Magnetic molding compound for inductors

To address this, Resonac focused on coupling agents (additives). Since there are many types of coupling agents, evaluating all of them experimentally would require significant time and cost. Instead, we used advanced reaction analysis based on quantum chemical calculations to clarify how coupling agents affect bonding between resin and coating on magnetic powder. This enabled us to identify and select the optimal coupling agent, resulting in a 1.4-fold improvement in bending strength compared to conventional coupling agents.

The technology used in this development is expected to enhance bonding strength between resin and various metal-containing materials, enabling application to a wide range of resin–metal composites regardless of the type of metal.

At Resonac’s Research Center for Computational Science and Informatics, we combine “computational science,” which uses simulation analysis based on physical laws, with “information science,” which uses AI and data-driven analysis, to accelerate research, development, and business creation. We also enhance the value of our technologies by filing patents for innovations that can create new value.

Resonac will continue to contribute to the sustainable development of global society by rapidly delivering the functions demanded by the times.

*1 A value that represents the force up to which a material can be bent before cracks form or it fails.

*2 An inductor is a passive electronic component in which a conductor is wound into a coil. Types include wound, thin-film and multilayer inductors. They are classified into high-frequency circuit inductors for selecting high/low frequency signals and reducing signal noise, and power inductors used in power circuits for voltage control.