July 08 2025

[Key Points of the News Release]

●Resonac and Tohoku University have commenced full-scale examination to apply the technology for producing SiC from silicon sludge and CO2 to the crystal growth of materials for SiC power semiconductors.

●This technology applies the carbon recycling technology known as “mineralization,” which reacts CO2 with solid materials, to recycle silicon sludge and CO2, thereby creating valuable raw materials for SiC.

●If this technology is put into practical use, SiC power semiconductors will not only contribute to energy conservation as products but also enable reduction of CO2 emissions, recycling of silicon sludge, and reutilization of CO2 simultaneously during the manufacturing process. This will make it possible to reduce environmental impact across the entire lifecycle of SiC power semiconductors.

[Overview]

Resonac Corporation (President and CEO: Hidehito Takahashi, hereinafter “Resonac”) and Graduate School of Engineering, Tohoku University (Dean: Akinori Ito, hereinafter “Tohoku University”) have been conducting fundamental research since 2024 to explore the application of silicon carbide (SiC) powder, produced from silicon sludge generated during the silicon wafer manufacturing process and carbon dioxide (CO2), as raw material for the growth of SiC single-crystal materials used in power semiconductors. If this technology is successfully commercialized, SiC power semiconductors will not only contribute to energy conservation as products but also enable reductions in CO2 emissions during the manufacturing process, the recycling of silicon sludge and CO2, and the overall reduction of environmental impact throughout their lifecycle.

Resonac and Tohoku University have completed the basic research phase and have now commenced full-scale studies aimed at practical applications.

[Detailed Explanation]

Background of the Research

In recent years, the impact of climate change, including natural disasters, has become increasingly severe. In response to this situation, countries around the world are strengthening regulations on greenhouse gas emissions, making the reduction and effective utilization of CO2 a global challenge. Particularly in the manufacturing industry, reducing CO2 emissions during production processes is an urgent task, while the recycling of waste materials is also strongly demanded. Among these, silicon wafers, which are indispensable for production of semiconductors and solar panels, generate significant amounts of silicon sludge as industrial waste during the cutting process, necessitating its recycling. To address these challenges, Tohoku University is conducting research to synthesize SiC by reacting CO2 with silicon sludge. This technology applies carbon recycling techniques through “mineralization,” which involves reacting CO2 with solid materials. By recycling both silicon sludge and CO2, it creates valuable SiC raw materials. This approach is expected to serve as a low-environmental-impact technology, replacing conventional high-energy-consuming processes.

This initiative

Resonac manufactures SiC epitaxial wafers (SiC epi-wafers), which are created by growing epitaxial layers on SiC single-crystal substrates. SiC epi-wafers serve as critical materials for power semiconductor devices used in electric vehicles (xEVs) and industrial equipment. Compared to conventional silicon (Si) wafers, SiC epi-wafers offer reduced power loss and heat generation during power conversion, contributing to energy saving. However, the synthesis of SiC requires high temperatures and significant power, posing challenges in reducing the environmental impact of the manufacturing process.

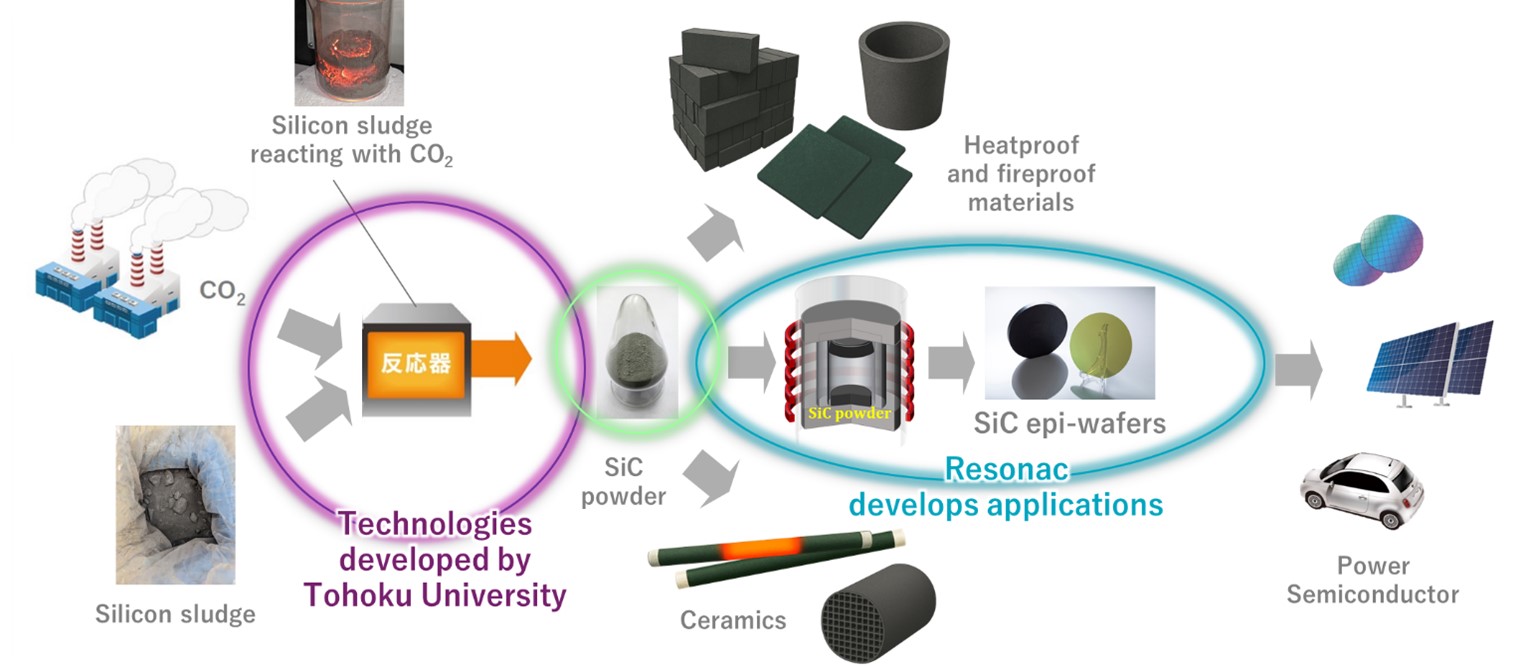

To address this challenge, Resonac and Tohoku University initiated fundamental research in 2024 to develop SiC powder using silicon sludge and CO2 as raw materials, with the aim of applying it as a growth material for SiC single crystals used in power semiconductors. In this study, Tohoku University synthesized SiC powder by heating silicon sludge and CO2 with microwaves at the carbon recycling demonstration research hub, while Resonac worked on applying the SiC powder to SiC single crystal substrates. Recently, the fundamental examination, including the characterization of the crystals obtained through this research, has been completed. Moving forward, comprehensive studies for practical application will be pursued.

If this technology is put into practical use, it is estimated that the CO2 reduction effect per 100 tons of SiC powder will reach the equivalent of 110 tons of CO2. This is expected to significantly contribute to the further promotion and widespread adoption of SiC power devices, which enable energy conservation and CO2 reduction.

Future Developments

By applying the SiC powder created using Tohoku University’s “mineralization” technology to Resonac’s “Best-in-Class” SiC epi-wafers, we aim to achieve a reduction in environmental impact throughout the lifecycle of power semiconductors and contribute to the realization of a sustainable global society.

Image diagram of the recycling process for silicon sludge and CO2

[Comments from Both Parties]

Yoshiteru Hosaka, Theme Leader, Technology Development Department, SiC Division, Device Solutions Business Unit, Resonac

Resonac has achieved world-class quality in the production of “SiC epi-wafers,” which are produced by growing epitaxial layers on SiC single-crystal substrates. In recent years, Resonac has also succeeded in developing technology to produce SiC epi-wafers with large-diameter of 8 inch. This technology, which enables the production of SiC wafers from CO2 and silicon sludge, has a significant impact both on the supply chain and on reducing environmental burdens. By leveraging the expertise and knowledge cultivated over many years as a dedicated manufacturer of SiC epi-wafers, I am confident that this collaborative research will bring Resonac closer to fulfilling its purpose of “Change society through the power of chemistry.”

Jun Fukushima, Assistant Professor, Department of Applied Chemistry, Graduate School of Engineering, Tohoku University

Amid the urgent need for global warming countermeasures and waste reduction, our research group has developed an innovative process to convert CO2 and silicon-based industrial waste into valuable resources. The key feature of this process lies in its ability to transform CO2, which is stable gas, into high-purity SiC with low energy consumption, offering a promising solution to both waste management and greenhouse gas reduction. Looking ahead, we aim to expand its application across diverse fields such as electric vehicles and renewable energy sectors. By accumulating practical demonstrations, we seek to enhance industrial competitiveness and present concrete measures toward achieving carbon neutrality and a circular economy by 2050.

[About Resonac]

Resonac is a functional chemical company that produces and sells products related to semiconductor and electronic materials, mobility, innovation enabling materials, chemicals, etc. The Company has a wide variety of materials and advanced material technologies applicable to midstream to downstream of supply chains of various products. In January 2023, Showa Denko and former Hitachi Chemical merged into the Resonac. The trade name “RESONAC” was created as a combination of two English words, namely, the word of “RESONATE” and “C” as the first letter of CHEMISTRY. As a “co-creative chemical company,” Resonac aims to continue growing and enhance its corporate value through co-creation. The Company recorded net sales of about 1.4 trillion yen in 2024, and its overseas sales accounted for 56% of net sales. The Company has deployed production/sales bases in 24 countries and regions and continues operating its business globally (as of February 2025).

[Regarding the Commissioned Project “Development of Carbon Recycling and Next-Generation Thermal Power Generation Technology / Next-Generation Thermal Power Generation Technology Promotion Project / CO2 Effective Utilization Technology Development and Demonstration Project at Research Bases” (Basic Research Area)]

New Energy and Industrial Technology Development Organization (NEDO), as part of its initiative “Development of Carbon Recycling and Next-Generation Thermal Power Generation Technologies,” is establishing a carbon recycling demonstration research hub within the premises of Osaki Power Plant of the Chugoku Electric Power Company, Incorporated. While demonstration research on next-generation thermal power generation technologies, such as CO2 separation and recovery-based oxygen-blown Integrated coal Gasification Combined Cycle (IGCC), is currently underway at the plant, this new initiative focuses on the development of carbon recycling technologies that utilize CO2 separated and recovered from the plant’s exhaust gases to produce chemicals, fuels, and minerals. By creating an environment conducive to efficient and concentrated research and development of various carbon recycling technologies, the project aims to accelerate technological development and achieve early practical application of these technologies.